Designed for Modulating and On/Off Service, the Bray Series 19 & 19L Segmented Rotary Control Valve offers faster flow consolidation than linear valves in a small form factor. It features bi-directional bubble-tight shutoff and SIL 3 performance.

The explosion proof electric actuator is suitable for flammable or explosive gas, liquid and dust occasions. It can accept a 4 to 20mA signal and has opening signal position feedback.

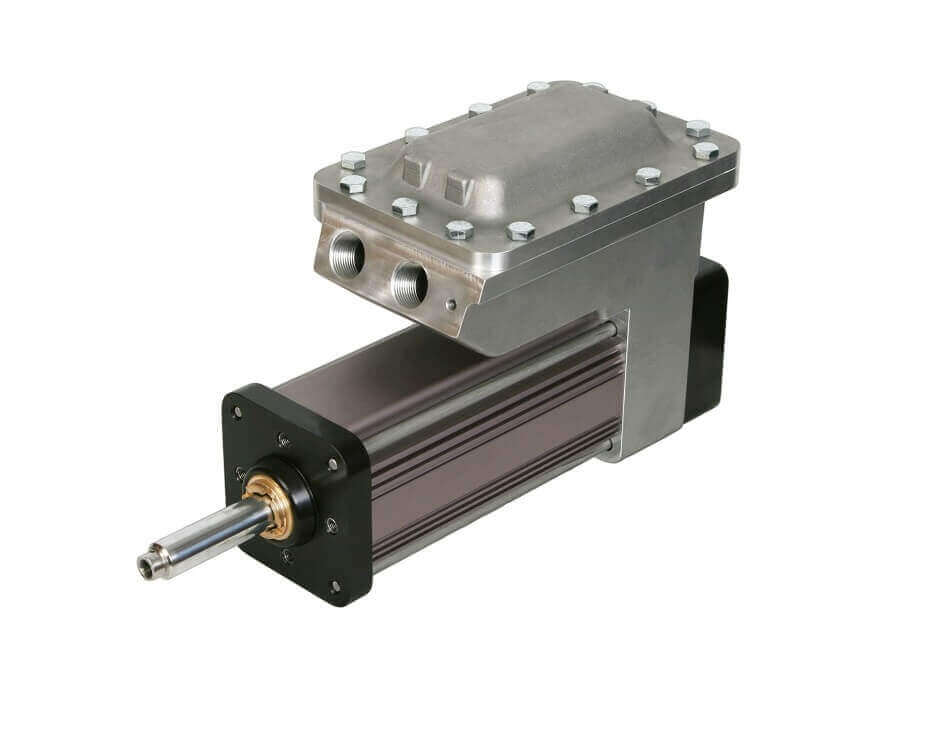

Pneumatic Double Acting Actuators

Stroke actuators convert air pressure into linear movement, controlling the position of a valve. These are ideally suited as control valves, providing strong closing forces and fast response times. They are also inherently explosion proof.

Depending on the model used, pneumatic double acting actuators can generate torque up to 10’025Nm at 6 bar / 87psi air pressure. They have a high capacity and provide precise positioning for all types of valves.

These are ideal for quarter-turn operating applications including small size ball valves (1″ and less), butterfly valves, plug valves and dampers. The WE weatherproof and XE explosion proof models are specifically designed for this type of valve automation use in hazardous areas. They feature simple design, easy operation and accurate calibration. These are the perfect choice when the requirement for higher control resolution is not required or where power outages may occur. The units are available with two-position or modulating control using a 4 to 20 mA input for position feedback.

Pneumatic Spring Return Actuators

The pneumatic spring return actuator is an economical option for a wide variety of applications. These actuators use compressed air or gas as their primary power source, and are paired with a solenoid valve commonly called a pilot valve. When the solenoid valve energizes, it receives an electric signal which opens or closes the air port within the actuator, thus opening/closing the ball valve.

These actuators are ideally suited for low-cycle applications that require a fail safe in the event of lost power. Their fail-safe mechanism snaps the valve to a pre-determined position when de-energized.

Unlike electrical actuators, pneumatic actuators cannot be accelerated. However, they can be slowed down by adding speed control valves to the air piping system. This will slow cycle speeds but not affect the actuator’s output torque.

Electro-Pneumatic Actuators

A pneumatic ball valve uses a hole in the body (the port or orifice) to control the flow of media. When the actuator is turned to the open position, the port opens up and allows media to pass through it. When the actuator is turned to the closed position, the port closes and prevents flow.

Pneumatic actuators can be a good choice for many applications, particularly those in which compressed air is readily available. However, when a high degree of safety is needed for flammable or explosive gas, an electric actuator may be required.

Gemini can provide an explosion-proof electric actuator for your ball valve. These units are suitable for use with a wide range of applications, including petroleum, chemical, metallurgy, light industry and paper-making. They also work well in conditions with a high temperature range and can handle higher pressures than traditional hydraulic actuators. The explosion proof design also eliminates the need for compressed air to be stored in a hazardous area, making them ideal for a variety of applications.

Analog Pneumatic Actuators

The AN/ANX series explosion proof actuator offers reliability and convenience with non-contact position sensing. This rack and pinion drive, double-acting actuator is constructed of epoxy-coated anodized aluminum to withstand aggressive process environments. It is available as an on/off or regulating actuator and comes in both standard and Intrinsically Safe options.

The actuator has a diaphragm mounted within an entirely enclosed volume. Air pressure from Port A and Port B will increase, until the diaphragm pushes against the spring pre-load at its maximum position, or the actuator reaches a final stop due to air loss. The actuator will then remain in this last position unless the position is reset using a manual operator or through the smart valve positioner. Smart positioners are available in both standard and Intrinsically Safe versions for Class 1 Div. 1 & 2 service. They are designed for ease of installation, simple calibration and efficiency. They are also highly durable and dependable with low power consumption.Explosion Proof Ball Valve with Positioner